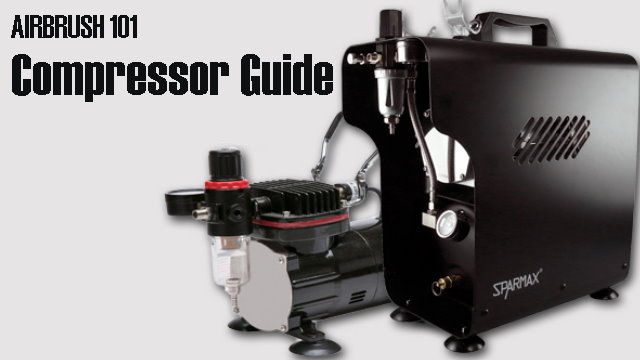

First and most important is your compressor! Airbrush compressors are used to provide a consistent supply of compressed air to airbrushes. Propellant cans are also available, however, these tend to be costly over an extended period of time. Compressors come in different models and sizes, and cheaper isn’t always better. When determining which compressor to get we need to ask ourselves the most important question of all- is it worth the investment? If you want a compressor to last a 6 hour gig and not burn your skin when you touch it, you need a GOOD Compressor.

You might have also stumbled across an industrial grade compressor, maybe at a car workshop etc. The difference between them is that our normal modelling compressor is quieter. If it has a tank… then it usually has an auto shut off function. The auto motor shut off also keeps it from over heating.

Sparmax Arism VIZ Product Description

Zero-maintenance, oil-less piston air compressor

Preset maximum pressure: 50 psi

Equipped with Silver Bullet Plus airbrush moisture trap

2M Braided hose

Detachable airbrush holder

Detachable power cord & plug: 100-240V

Pressure gauge

Below are some words and phrases which are commonly used in connection with airbrush compressors, especially when describing and comparing product specifications.

Air Source – unit or device capable of producing, or containing, pressurised air

cfm – often used to describe a measurement of air flow – cubic feet per minute

Moisture Filter – a device for removing water vapour from the pressurised air

Air Regulator – a device used to control and adjust air pressure (PSI or Bar)

PSI – an abbreviation of: pounds per square inch. Used to measure air pressure

Bar – a measurement used to quantify air pressure

(one psi = 0.068945 bar)

Air Pressure Regulators

Modern air pressure regulators, also called manometers, may also incorporate a water trap / water filter. Most air pressure regulators / water traps also have a pressure gauge dial showing measurements in psi and bar. A pressure regulator screws directly on to the air outlet of an air compressor and is essential as it controls the air pressure being delivered to the airbrush. A water trap is highly recommended as water vapour is not only present in the everyday air but is also produced when you place through a mechanical process such as pressurising it. Water will cause many issues with paint if not removed from the air supply.

Mini In Line Air Filters

Mini in line air filters are also available and can be connected to the airbrush male air inlet valve. The air hose then attached to the male air inlet of the mini in line air filter.

Although not essential they provide a secondary defence against water vapour if used in conjunction with a main pressure regulator / water trap.

Types Of Airbrush Compressors

Oil Filter – a device for removing oil from the pressurised air (many of the airbrush compressors are now of an oil-less design.

Diaphragm Compressor -The compression of air occurs through the use of a flexible membrane which oscillates. Maximum pressure output is in the region of 40PSI.

Piston Compressor – The piston compressor is the most common choice for airbrushing. It is usually more powerful than a diaphragm compressor and produces a higher volume of air.Piston compressors operate at relatively low noise levels, however, these noise levels vary between manufacturers. Most are now oil-less design which boasts zero mantainence.

Compressor Designs

While you will see many makes and models of compressors, almost all of them will have the basic design and component. Some of the compressors will come with a tank. We have to stress that if yours do come with a tank. Its best practise to bleed out the stored compressor air after every usage. Normally, we would always recommend a normal size compressor capable of regulating air pressure output. Some mini compressors do not have this regulating function in which they are set to produce compressed air at a single pressured setting.